Granule Packing Machine Coffee Sugar Seasoning Pack Cereal Packing Machine

Purchase Qty. / FOB Price:

Quick Details

Product Details

The granule packaging machine is suitable for automatic packaging of loose, non-sticky granular materials in pharmaceuticals, food, daily chemicals, pesticides, plastic products and special industries. Such as: peanuts, seeds, traditional Chinese medicine, feed, granules, pellets, monosodium glutamate, salt, sugar, soup, oatmeal, tea, activated carbon, washing powder, desiccant and other materials packaging

This machine features:

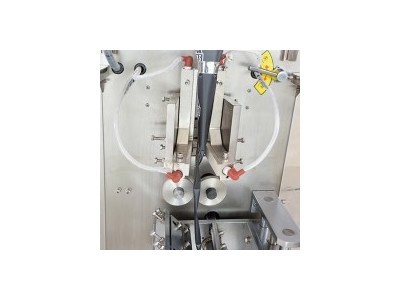

1. The packaging machine can automatically complete the bag-pulling, bag-making, filling, metering, sealing, bag-cutting, counting, hot-pressing batch number, and output product during the packaging process.

2. imported PLC control system, Chinese and English display, only need to set the required parameters (filling bag length, etc.) in the displayable setting unit, so as to achieve the best packaging effect.

3. Stepper motor control, the system has high accuracy, just adjust the parameters to change the length of the bag making, and it is accurate and accurate through photoelectric control, and obtains a complete trademark pattern.

4. The overall frame of the machine is made of stainless steel, the surface is finished, smooth, easy to clean and sterilized.

5. The parts in contact with the material are made of high-quality stainless steel, which meets the requirements of GMP. Modular design of related components, easy to disassemble and assemble, and strong versatility.

6. Optional: thermal transfer coding machine, ribbon coding machine, feeding machine, finished product conveyor.